The UNSW team who developed the three-minute cold brew - Shih-Hao Chiu, Dr Francisco Trujillo and Nikunj Naliyadhara.

Image credit: UNSW Cecilia Duong.

UNSW Sydney engineers have utilised sound waves to cut the time it takes to make a cold brew coffee from many hours down to mere minutes.

Fans of cold brew coffee often rave about the smoother, less acidic and less bitter taste compared to a regular hot brew.

There’s just one major problem – it takes anywhere from 12 to 24 hours to fully steep the grounds and allow the flavours to slowly be extracted using only cold water.

That’s far from ideal if you want or need your caffeine fix in a hurry in the morning.

However, engineers from UNSW have now developed a new way to make cold brew coffee in under three minutes – just like a regular hot brew – without sacrificing on the taste experience.

The process involves using an ultrasonic reactor to speed up the brew of the grounded coffee beans, with the research published in Ultrasonics Sonochemistry.

The ultrasonic brew

Addressing the challenge of speeding up the brewing process of a cold brew, the UNSW team led by Dr Francisco Trujillo, used an existing model of a Breville espresso machine and superimposed their own patented sound transmission system.

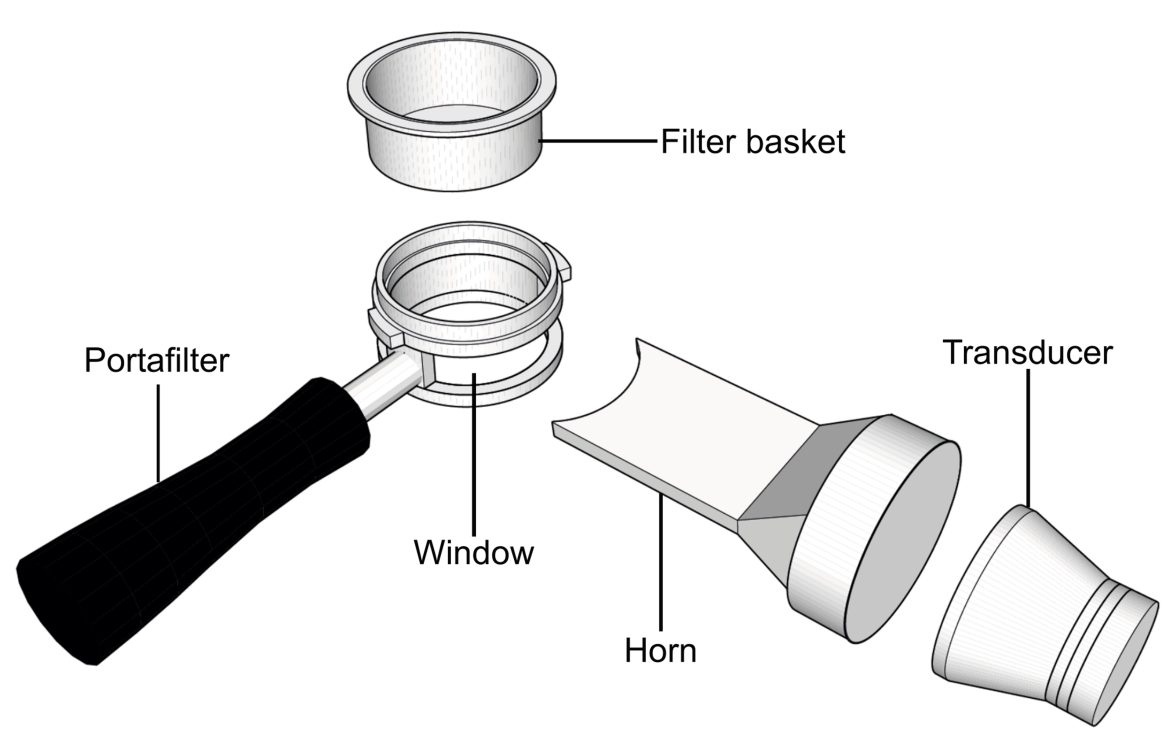

The system connects a bolt-clamped transducer with the brewing basket via a metallic horn – transforming a standard espresso filter basket into a powerful ultrasonic reactor.

The reactor works by injecting sound waves at a frequency of 38.8 kHz at multiple points through its walls – generating multiple regions for acoustic cavitation within the reactor.

The new faster cold brew system subjects coffee grounds in the filter basket to ultrasonic sound waves from a transducer, via a specially adapted horn.

The study also found that this setup can double the extraction yield and caffeine concentration compared to unsonicated samples.

Dr Trujillo, corresponding author of the paper and UNSW food processing engineer in the School of Chemical Engineering, says the ultrasound process speeds up the extraction of the oils, flavours and aroma of the ground coffee.

“Ultrasounds accelerate the extraction process due to acoustic cavitation,” he says.

“When acoustic bubbles collapse near the grounded coffee, they generate micro-jets with enough force to pit and fracture the coffee grounds – intensifying the extraction of the aroma and flavours of the brew.

“And the acceleration is enormous – we are reducing what would typically take 12 to 24 hours to less than three minutes.”

Dr. Trujillo says the aim was to make the process as easy as making a regular espresso coffee.

“We’re able to demonstrate that this can be adapted to existing espresso machine,” he says.

“We are very excited about developing this technology that can be used by companies that already manufacture coffee machines, so consumers can enjoy an ultrasonic cold brew at home in less than three minutes.

“Very importantly, this breakthrough opens the door for coffee shops and restaurants to produce on-demand brews comparable to 24-hour cold brews, supplying the rising demand while eliminating the need for large semi-industrial brewing units and the associated requirement for extensive refrigeration space.”

Same taste in less time

Collaborating with researchers from University of Queensland, samples of coffee were sent to the Queensland Alliance for Agriculture and Food (QAAFI) where they underwent a thorough sensory analysis.

The samples included cold brew sonicated at room temperature for one minute, the second was sonicated for 3 minutes, and the third was a regular 24 hours stepped brew at four degrees Celsius without sonication.

They were evaluated on their aroma, texture, flavour, and aftertaste attributes.

“Compared to the 24-hour brew, the sonicated one-minute brew sample received similar ratings, especially in flavour, aftertaste attributes including bitterness, sourness, fullness texture and aroma,” says Dr. Trujillo.

“However, it scored lower in aroma intensity and dark chocolate aroma. This suggests that the sonicated 1-minute sample is slightly under-extracted compared to the 24-hour cold brew.

“Meanwhile, the sonicated three-minute sample provided a similar dark chocolate aroma and aroma intensity to the 24-hour cold brew, but slightly more bitter.

“The results of the sensory study showed that a sonication time between one and three minutes is ideal for creating a coffee comparable with 24-hour cold brew coffee, depending on the interest of customers.”

University of Queensland Sensory Scientist and Flavour Chemist Professor Heather Smyth, a co-author of the paper, said the new method created a coffee as good as cold brew steeped overnight.

“Our trained sensory panel tastings proved that we can get a very similar taste profile to either a traditional cold brew or an espresso in the time it takes to brew a hot espresso,” Prof. Smyth said.

“Further work could explore different types of beans, different regions of beans and for companies or cafes that specialise in single origin or high-quality beans, this would be another string to the bow to show yet another dimension of coffee.

“Once again, Australia has new technology at our fingertips that moves on from traditional methods to modern methods of coffee making to give consumers a new premium experience.”

Shaking up the beverage industry

Ultrasounds can be applied to several areas across the food industry including drying, extraction, emulsification and crystallisation – making the process faster and more efficient.

Dr. Trujillo says this technology can be also used to speed up the brewing process of teas as well.

“With this technology, we’re offering coffee shops, restaurants and even home coffee-brewers the chance to produce on-demand brews, eliminating the need for large brewing and refrigeration units.”

This article was orginally published by USNW.